Precision MIG/MAG Welding with Silicon Nitride Gas Nozzles

$305-49 Piece/Pieces

$2650-499 Piece/Pieces

$24≥500Piece/Pieces

| Payment Type: | T/T |

| Incoterm: | FOB,CIF |

| Transportation: | Air |

| Port: | Shanghai Pudong International Airport |

$305-49 Piece/Pieces

$2650-499 Piece/Pieces

$24≥500Piece/Pieces

| Payment Type: | T/T |

| Incoterm: | FOB,CIF |

| Transportation: | Air |

| Port: | Shanghai Pudong International Airport |

Model No.: Customized according to drawings or samples

Brand: TecCeram

Place Of Origin: China

Species: Ceramic Tubes

Application: Industrial Ceramic

Processing Service: Cutting, Punching, Moulding

Colour: Grey or dark

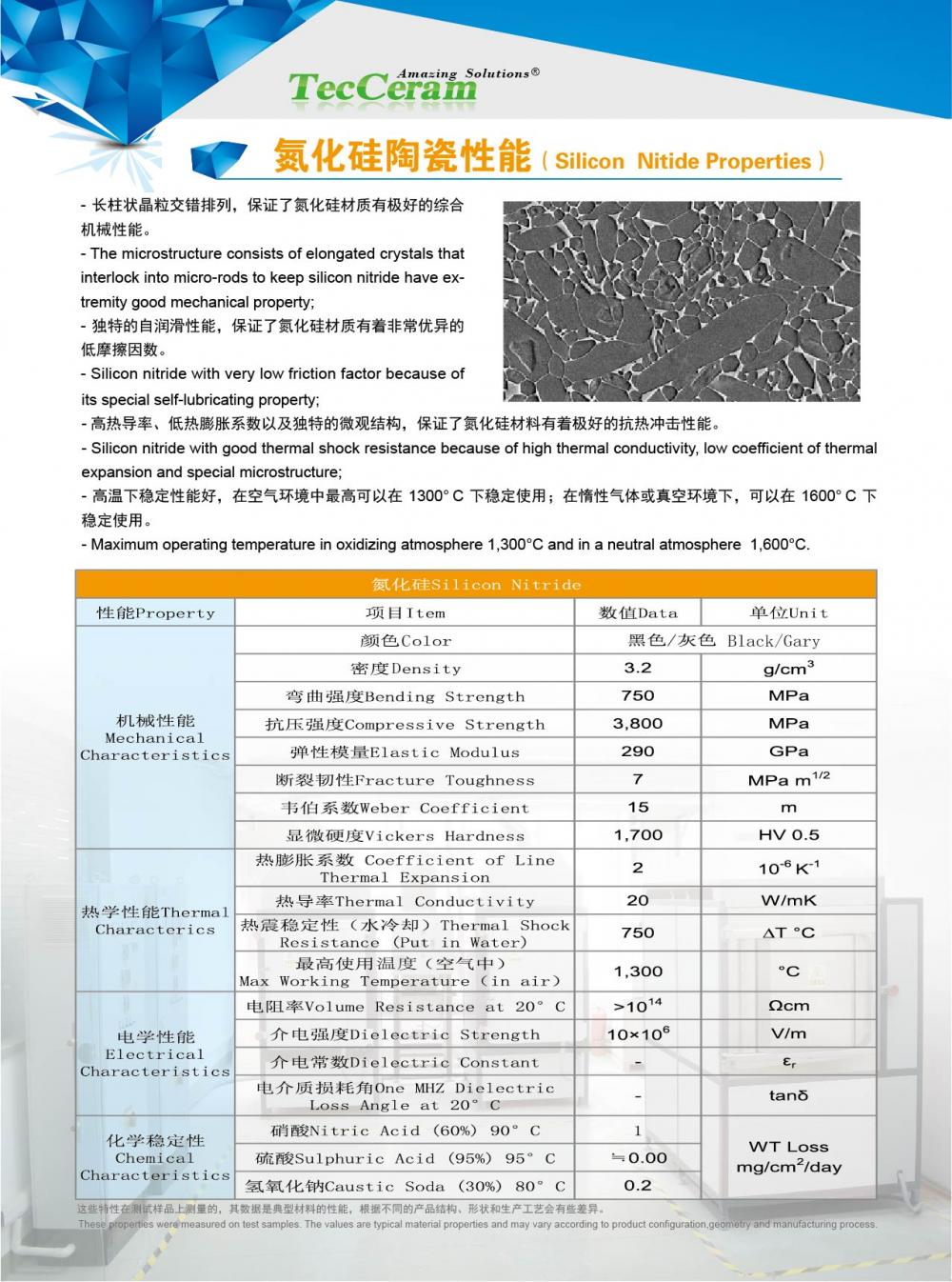

Density: >3.2g/cm3

Bending Strength: 850MPa

Fracture Toughness: 7MPa.m1/2

Vickers Hardness: 1700 (Hv0.5)

The ceramic raw material of these silicon nitride gas nozzles is imported from Germany. After shaping by cold-isosactic-pressing (CIP), debinding and gas pressure sintering, the nozzles are grinded and polished by diamond.

Our silicon nitride Ceramic Gas Nozzles are far less susceptible than steel nozzles to the high stress levels placed on them during the welding process. The surface of the ceramic material prevents welding drops from adhering to it and reduces slag formation.

In MIG/MAG welding applications, for instance when welding thin-walled metals in vehicle body construction, it is essential to ensure a perfect weld seam along with an even, uniform flow of gas. To achieve a constant flow of gas from the nozzle, the nozzle opening used on the robot arm must remain clean at all times. MIG/MAG gas nozzles made of silicon nitride ceramics make this possible: They show virtually no traces of deposits or adhesion of metal spray or slag, thus ensuring long service life and precision in MIG/MAG welding.

The smooth surface and wear resistance of Silicon Nitride Ceramics ensures lasting, high-quality weld joints. This means ceramic gas nozzles made from this material require less frequent cleaning and replacement: Depending on their positioning, our silicon nitride ceramic gas nozzles optimized for welding applications offer a service life many times that of steel or hard chrome-plated copper. This reduces the machine downtime required for replacing these elements – something that has been proven during over three years of use of CeramTec silicon nitride ceramic gas nozzles in the automotive industry.

MIG/MAG Gas Nozzles made of Silicon Nitride Ceramics

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.