Wear-resistace slicon nitride ceramic punching needles

$2010-99 Piece/Pieces

$15100-499 Piece/Pieces

$13≥500Piece/Pieces

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Air |

| Port: | Shanghai Pudong International Airport |

$2010-99 Piece/Pieces

$15100-499 Piece/Pieces

$13≥500Piece/Pieces

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Air |

| Port: | Shanghai Pudong International Airport |

Model No.: Customized according to drawings or samples

Brand: TecCeram

Whether CNC Machine Tool: Cnc

Status: New

Machine Type: Punching Machine

Place Of Origin: China

Core Selling Point: High-Accuracy

Warranty Period: 1 Year

Marketing Type: New Product 2020

Core Components: Bearing, Pump, Gear, Gearbox, Pressure Vessel, Engine

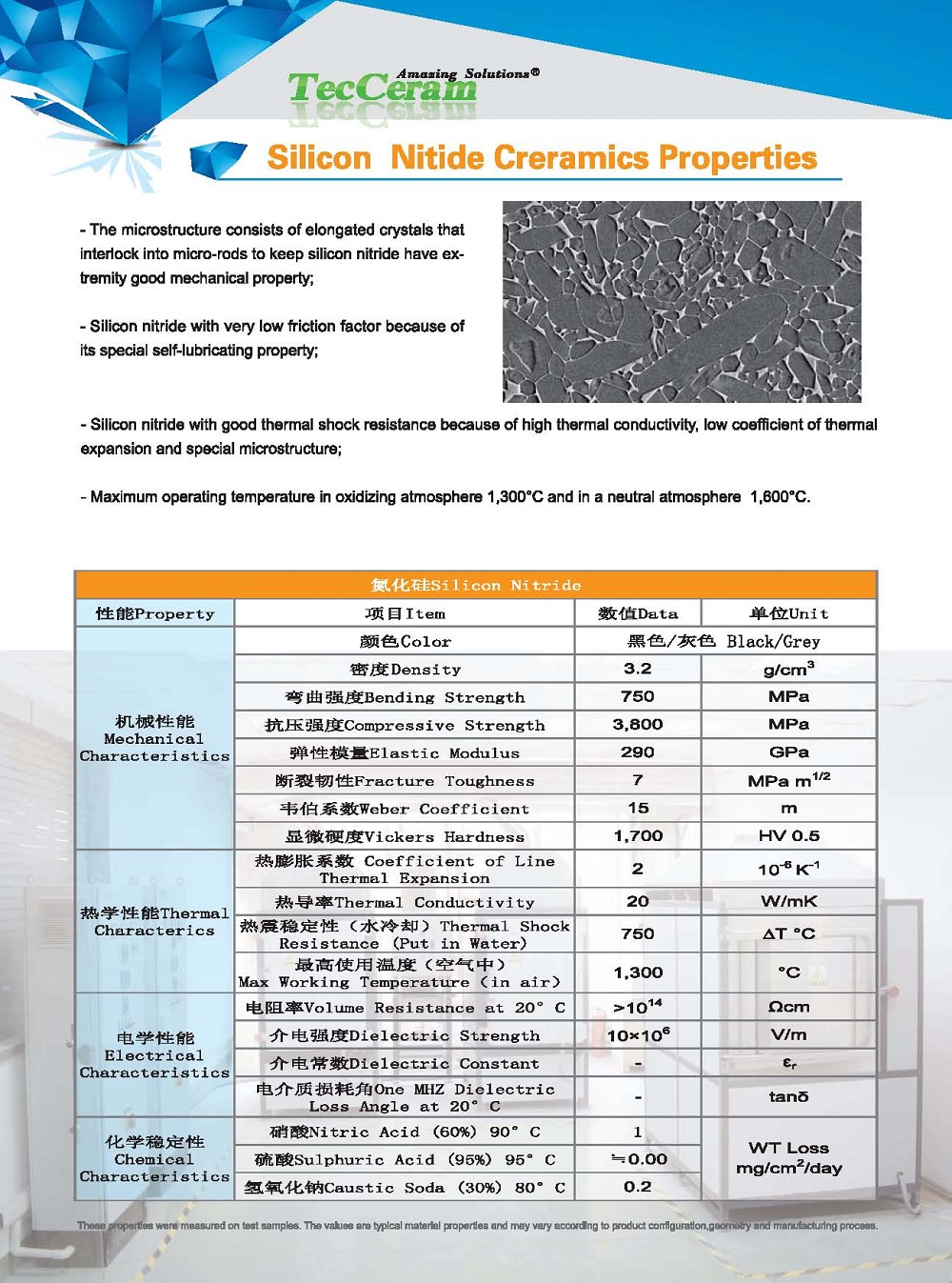

Density: 3.22g/cm3

Color: Grey

Bending Strength: 750MPa

Fracture Toughness: 7MPa.m1/2

Vickers Hardness: 1700 (Hv0.5)

The raw material of these silicon nitride ceramic punching needles is imported from Germany. The products produced by this material have excellent thermal stability, high strength, and wear resistance. These high stregth pins play a crucial role during application.

Here are some key features and benefits of using silicon nitride ceramic positioning pins for automotive welding:

1. High temperature resistance: Silicon nitride ceramic pins can withstand extreme temperatures, making them suitable for automotive welding applications where high heat is generated. They can maintain their structural integrity and dimensional stability even at elevated temperatures.

2. Excellent mechanical properties: These pins have high strength and hardness, allowing them to withstand the forces and stresses encountered during welding operations. They can maintain their shape and resist deformation, ensuring precise positioning of the components.

3. Low thermal expansion: Silicon nitride ceramic has a low coefficient of thermal expansion, which means it expands and contracts minimally with temperature changes. This property helps in maintaining accurate positioning during the welding process, as the pins do not undergo significant dimensional changes due to heat.

4. Wear resistance: The ceramic material used in these pins has excellent wear resistance, ensuring a longer lifespan and reduced maintenance requirements. This is particularly important in automotive welding applications, where the pins are subjected to repeated use and contact with other metal surfaces.

5. Chemical inertness: Silicon nitride ceramic is chemically inert, meaning it does not react with most automotive welding environments or the materials being welded. This inertness prevents contamination or adverse reactions that could affect the quality of the weld joint.

6. Electrical insulation: Silicon nitride ceramic is an excellent electrical insulator. This property is beneficial in automotive welding, as it helps prevent electrical currents from flowing through the pins, ensuring safety and preventing unwanted interference.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.