Alumina wafer polishing plate for semiconductor industry

$3001-4 Piece/Pieces

$2605-9 Piece/Pieces

$245≥10Piece/Pieces

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai Pudong International Airport |

$3001-4 Piece/Pieces

$2605-9 Piece/Pieces

$245≥10Piece/Pieces

| Payment Type: | T/T |

| Incoterm: | FOB |

| Transportation: | Ocean,Land,Air,Express |

| Port: | Shanghai Pudong International Airport |

Model No.: HPA012

Brand: TecCeram

Place Of Origin: China

Species: Ceramic Parts

Application: Industrial Ceramic

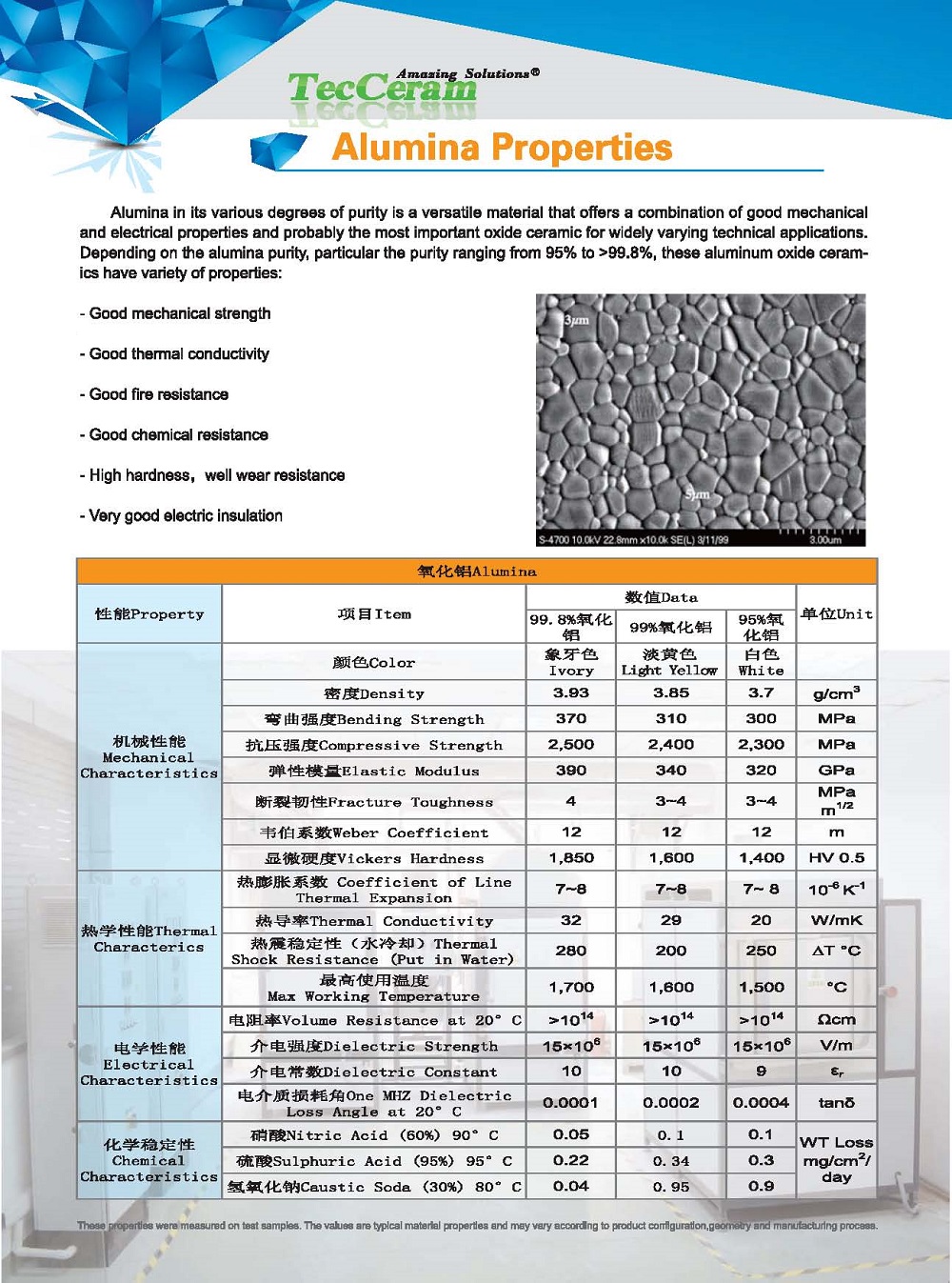

Material: Alumina Ceramic

Processing Service: Bending, Welding, Cutting, Punching, Decoiling, Moulding

Color: Ivory

Purtiy: 99.8%

Density: >3.93g/cm3

Bending Strength: 370MPa

Vickers Hardness (Hv0.5): 1850MPa

| Selling Units | : | Piece/Pieces |

| Package Type | : | Wood case or paper box |

| Picture Example | : |

|

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.